Molding Automation

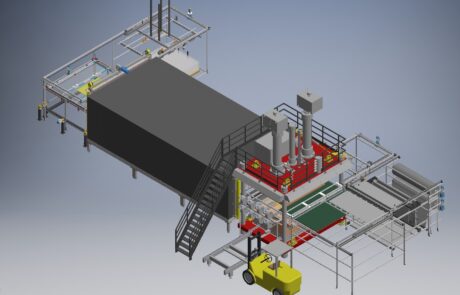

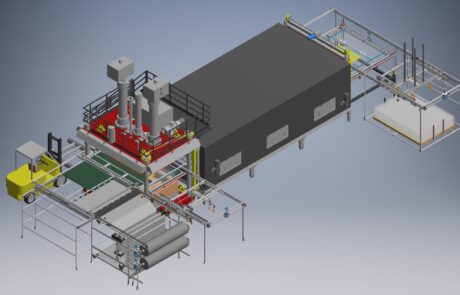

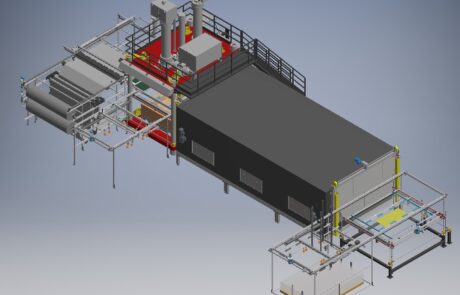

DEVELOPING AN AUTOMATED MOLDING PLANT FOR INSULATION FOILS MADE OF LWRT

Customer:

Intec S.r.l.

Software:

Project:

Automated molding plant for insulation foils made of LWRT coupled with PVC textile for the automotive industry

The challenge:

Replace the existing production plant with a system able to reduce the cycle time within the limits required by the final customer and that was easy reconfigurable according to the various sizes of foils to be mold

Our intervention:

We developed the whole plant, with the exception of the oven that was entrusted to a specialized company

The first step was to test LWRT samples to understand their behavior once heated, checking the cooling time and hot deformability. In this way it was possible to validate the anchoring system on the transport frame and define the time limit between the exit of the foil from the oven and the forming beginning.

We have then divided the system into various areas and developed the various groups first individually and then integrating them into the general assembly to check for interference and define the placements of the fixing points.

The areas of the plant are organized as follows:

Inlet area:

LWRT foil lifting system via suction cups, translation and fixation of the sheet on the transport frame. Frame handling system towards oven conveyor. Elevator for return frame.

Oven:

three stations ventilated tunnel oven, maximum working temperature 280°C, maximum temperature 300°C; upper floor for the outward trip of the frame, lower floor for return.

Hydraulic press:

press plate for sheets of maximum size 1950 x 2700 mm, closing force 400 ton, opening stroke 1500 mm. Plates with thermostation predisposition. Guides for extraction of the press lower plate to allow the mold replacement. Textile grip system by pliers.

Textile loading and cutting area:

frame for mounting two textile rolls Ø600 x 3000 mm, unrolling system, grippers, textile cutting system, infrared lamps for textile preheating an trolley for positioning the textile under the mold top.

Unloading area:

formed part grip system by suction cups, translating cart from press to finished parts collecting cart.

The result:

we were able to meet all customer requests reducing the empty cycle time (i.e. excluding forming time) to 80 seconds compared to about 240 seconds of the current plant.

Size:

the area occupied by the plant is about 11 x 20 m.

Main suppliers:

- oven built by Idrocalor S.r.l. https://www.idrocalor.com/

- electrical system and plc programming by Chipcore http://www.chipcore.eu/

Thanks are also to Eng. Francesco Boato for the precious work done.